Summary:

• Scientists have developed a new process to turn biodiesel waste into useful products

• The method reduces emissions and energy use by working at room temperature and on site.

• This innovation helps biodiesel producers make more profit and supports a greener economy

Biodiesel is a type of fuel made from renewable sources like plant oils, animal fats, and even used cooking oil. It offers a more environmentally friendly alternative to traditional diesel because it is biodegradable and produces fewer greenhouse gas emissions. However, making biodiesel also creates a waste product called crude glycerol. For every tonne of biodiesel produced, about 100 kilograms of this waste is generated.

Crude glycerol is not easy to recycle. It contains leftover chemicals and impurities from the fuel-making process, making it difficult to reuse. Most biodiesel producers end up selling it at a low price to companies that refine it. These companies often turn it into solketal, a valuable solvent used in making medicines, cosmetics, industrial products, and as a fuel additive. The global market for solketal is estimated to be worth $78 billion.

The traditional way of refining crude glycerol into solketal is costly and harmful to the environment. It involves shipping the waste, sometimes overseas, which increases emissions. The refining process also uses a lot of energy because it requires high temperatures and pressures.

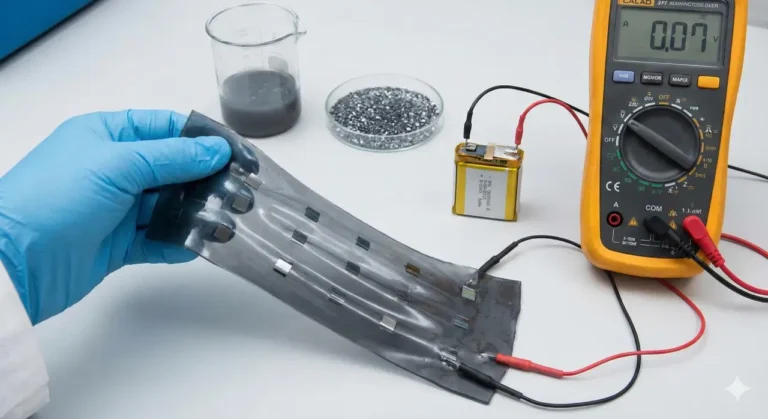

A team of scientists from R3V Tech, a company started by experts at Loughborough University, has created a new solution. Their process uses electricity to transform crude glycerol into solketal directly at the biodiesel plant. This method is called an electrochemical process. It works at room temperature and normal air pressure, which means it uses much less energy than older methods.

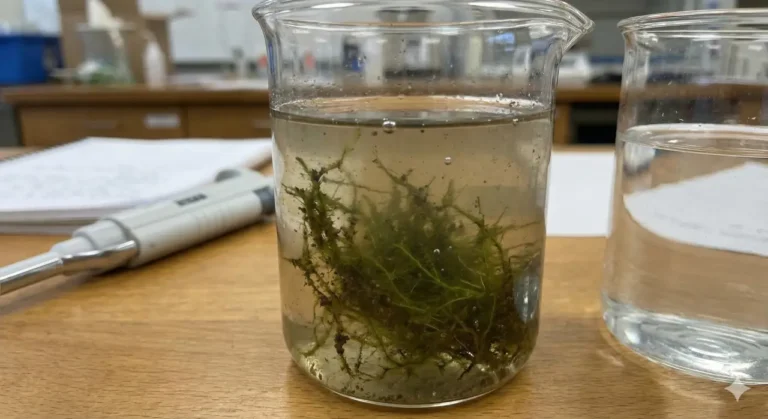

Here’s how the process works: First, the crude glycerol is filtered and mixed into a special solution. Carbon dioxide is then added to this mixture. The combined solution is passed through an electrochemical reactor, where electricity triggers a reaction that changes the waste into solketal. The final product is collected as a liquid, ready to be used or sold.

This new approach offers several benefits. By converting crude glycerol on site, biodiesel producers can avoid the costs and emissions linked to transporting waste. They can also make extra money by selling the solketal or using it themselves. The process even uses waste carbon dioxide, further lowering its impact on the environment.

R3V Tech is working to scale up this technology so it can be used in real-world biodiesel plants. Their goal is to create a compact, modular unit that producers can easily install and operate. This would make it simple for any biodiesel company to turn their waste into a valuable product, supporting a circular economy where resources are reused instead of thrown away.

By adopting this innovation, biodiesel producers can cut down on waste, lower their environmental footprint, and improve their bottom line. It’s a promising step toward making renewable fuels even more sustainable and profitable.

This article is based on information from a PR Environment campaign release about R3V Tech, a Loughborough University spin-out company, and its researchers Dr Adriano Randi (CEO) and Professor Benjamin Buckley (CSO).