Image is for illustrative purposes only.

Summary:

• A new pilot plant can capture carbon dioxide (CO2) from the air using much less energy than before.

• The technology uses special filter materials and a smart two-zone process to save energy.

•This approach could help fight climate change by removing CO2 already in the atmosphere.

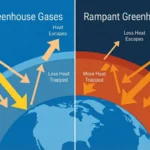

Removing carbon dioxide (CO2) from the air is an important part of tackling climate change. While cutting emissions is crucial, experts agree that we also need to take out some of the CO2 that’s already in the atmosphere. A new technology, recently tested in Austria, could make this process much more efficient and practical for everyday use.

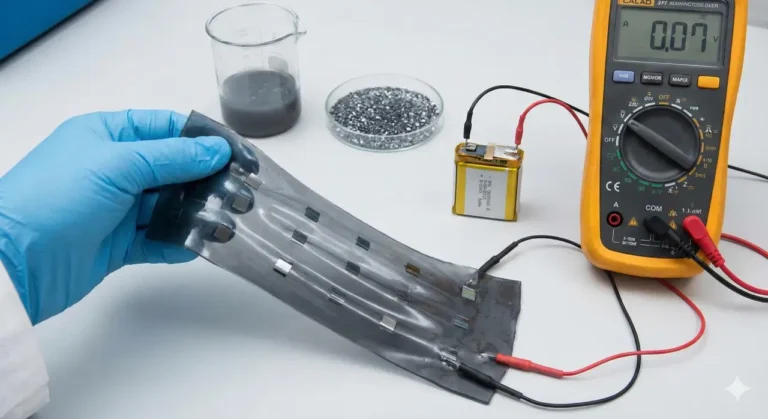

What’s New About This Technology: The new pilot plant, called the Austrian Pilot Unit 1 (APU1), is about the size of a truck container. It can remove 50 tons of CO2 from the air each year. What makes it special is how little energy it needs: less than 2,000 kilowatt-hours (kWh) to capture one ton of CO2. For comparison, this is much lower than what most current systems require.

The plant is designed to be flexible. Smaller companies or even community groups could use just one unit. Larger organizations could combine several units to build bigger facilities. The team behind the project hopes to scale up to a 1,000-ton-per-year plant soon.

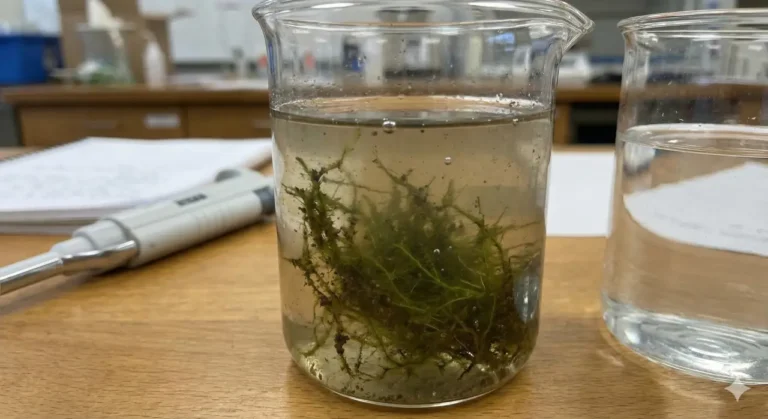

How Does It Work: The process uses materials known as amines, which can grab CO2 molecules from the air. These amines are attached to tiny solid particles, creating a filter. When air is pumped through the filter, the CO2 sticks to the amines, while the rest of the air passes through.

Eventually, the filter material fills up with CO2 and needs to be cleaned so it can be used again. This is done by heating the material, which releases the captured CO2 so it can be collected and stored. The filter is then ready to capture more CO2.

A Smarter, More Efficient System: In many older systems, both the filter and its container are heated together, wasting energy. The new approach uses a two-zone process. The filtering happens in a cool area, and when the filter is full, it’s moved to a separate hot area for cleaning. Only the filter material is heated, not the whole container. This clever setup saves a lot of energy.

The system can also use low-temperature heat—such as waste heat from factories or power plants—that would otherwise go unused. This makes the process even more efficient and could lower costs.

Why Does This Matter: Climate scientists agree that removing CO2 from the air is essential for meeting climate goals. Many climate models already assume that this kind of technology will be available and widely used in the future. If it’s not, keeping global warming in check will be much harder.

However, CO2 capture is not a substitute for cutting emissions. We still need to reduce the amount of CO2 we put into the air. But having effective, energy-saving ways to remove CO2 that’s already there gives us another important tool in the fight against climate change.

What’s Next: The team behind APU1 plans to keep improving the technology and make it available in different sizes. The goal is to allow more people and organizations to set up their own CO2 capture systems, much like how solar panels are installed today.

If this technology proves successful at larger scales, it could help remove significant amounts of CO2 from the atmosphere in a practical and energy-efficient way.

This research and pilot plant were developed through a collaboration between TU Wien, DAClab (USA), and DACworx (Austria), with the process designed by TU Wien and the pilot unit built and commissioned by the startups and TU Wien employees. The project was initiated and financed by Peter Relan, founder and president of the Dharma Karma Foundation.