Image for Illustrative Purposes Only.

Summary:

• Researchers are using langoustine shells, a food industry byproduct, to build parts of robots.

• Combining natural exoskeletons with synthetic materials could make robotics more sustainable.

• This approach could help recycle waste and inspire new uses for biological materials in technology.

When most people think of robots, they picture shiny metal arms or plastic gadgets. But a team of researchers at EPFL’s CREATE Lab is taking a different approach: they are building robotic parts using the leftover shells from langoustines, a type of shellfish often served in restaurants.

Why use shells in robots: Langoustine shells, called exoskeletons, are strong and flexible. In nature, these features help the animal move quickly and powerfully underwater. The researchers realized that these same qualities could be useful for robots, especially those that need to grip, lift, or move in water.

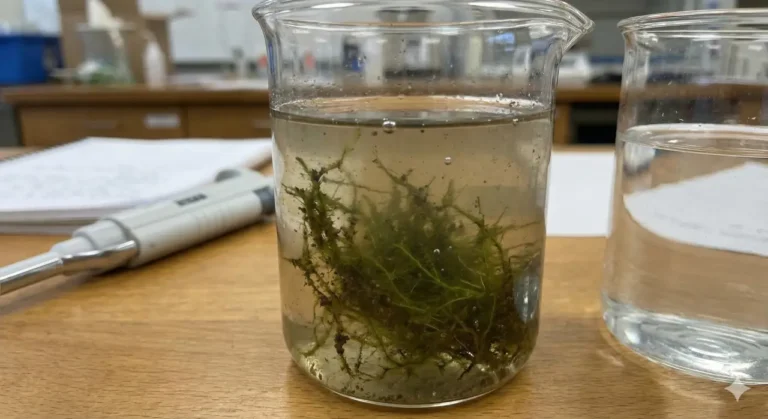

To turn the shells into robotic tools, the team first cleaned and prepared the exoskeletons left over from the food industry. They then added a soft, stretchy material called an elastomer inside the shell. This material helps control how each part of the shell bends and moves. Next, the shell is attached to a motorized base, which allows the robot to move the shell with precision. A layer of silicone is added on the outside to make the shell last longer.

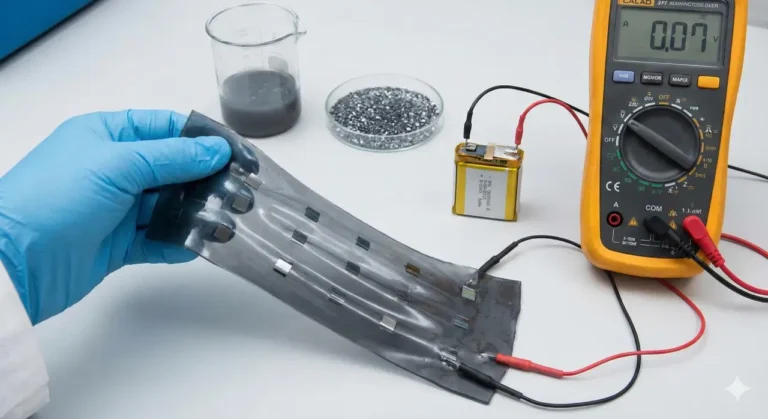

The result is a robotic manipulator that can pick up objects weighing up to half a kilogram. By using two shells together, the robot can grip items of different shapes and sizes, from a pen to a tomato. The team even built a swimming robot that uses shell “fins” to paddle through water.

One of the big advantages of this approach is sustainability. Instead of throwing away the shells, they are given a new purpose. Many of the synthetic parts can be reused, and the biological parts can be replaced with more food waste when needed. This “design, operate, recycle, repeat” process helps reduce waste and makes robotics a bit greener.

There are some challenges, though. Each langoustine shell is a little different, so robots made from them may not move exactly the same way. The researchers are working on ways to adjust for these differences, such as using smarter controllers.

Looking ahead, the team believes that using natural materials in technology could have many benefits. For example, similar ideas might be used in medical implants or devices that monitor the environment. Nature’s designs, while not always perfect, often solve problems in ways that artificial materials cannot.

This work shows that food waste can be more than just trash—it can be a building block for the technology of the future.

This research was published in Advanced Science by the CREATE Lab at EPFL’s School of Engineering. The study was led by researcher Sareum Kim, with contributions from lab head Josie Hughes and other co-authors.