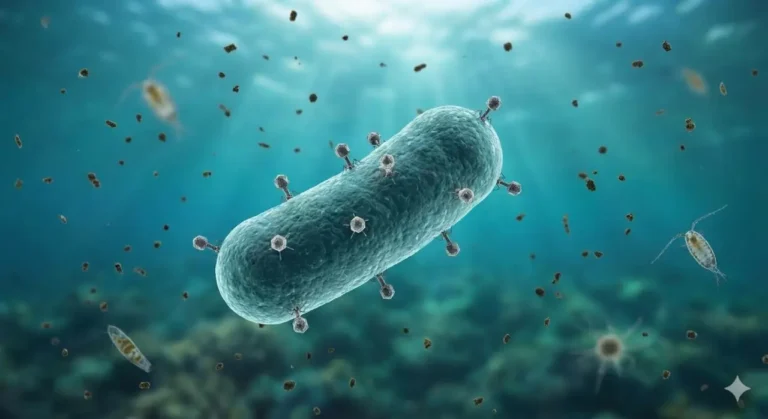

Image for Illustrative Purposes Only.

Summary :

• Scientists are exploring iron-nitrogen-carbon catalysts made from peat as a low-cost alternative to platinum in fuel cells.

• The structure of these catalysts, especially their tiny interconnected pores, is key to their performance.

• Using peat-based materials could make fuel cells cheaper and more sustainable, helping support cleaner energy systems.

Fuel cells are devices that turn hydrogen into electricity, with water as the only byproduct. They are seen as a promising technology for clean energy, but one big challenge is their cost. Right now, most fuel cells rely on platinum as a catalyst—a substance that speeds up the necessary chemical reactions. Platinum works well, but it is rare and very expensive.

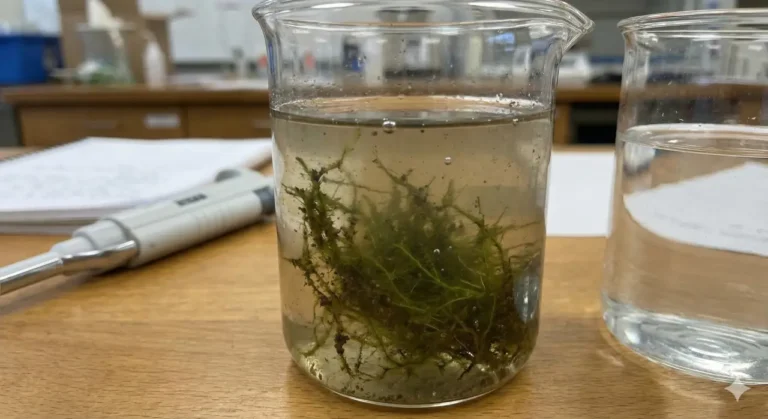

Researchers are now looking for ways to replace platinum with cheaper materials that still work efficiently. A new study shows that iron-nitrogen-carbon (Fe-N-C) catalysts, made from well-decomposed peat, could be a strong alternative. Peat is an organic material found in wetlands, and using it as a raw material is both low-cost and environmentally friendly.

The secret to these new catalysts lies in their structure. Imagine an ant colony, full of tiny, winding passages. In a similar way, these peat-based catalysts have a network of pores of different sizes. Hydrogen and oxygen molecules travel through these passages until they reach special sites where the chemical reaction happens, turning them into water and releasing energy.

The researchers discovered that not all Fe-N-C catalysts perform the same. They wanted to find out why some worked better than others. To do this, they created several samples, each with slightly different structures, by changing how they were made. They then used a special X-ray technique to look closely at the size, shape, and arrangement of the pores inside each sample.

What they found was that certain structural features made a big difference. For example, when the curves of the pores were at least three nanometres (a nanometre is a billionth of a meter), the catalyst worked best. This structure helped the fuel cell turn oxygen into water more efficiently and reduced the creation of unwanted byproducts like hydrogen peroxide.

By understanding these details, scientists can now design better peat-based catalysts on purpose, rather than by trial and error. This could make fuel cells much cheaper, since iron and peat are far less costly than platinum. Plus, using peat from places like Estonia means the materials are more sustainable and widely available.

If these peat-based catalysts continue to improve, they could help make fuel cells a more affordable and environmentally friendly choice for clean energy, supporting efforts to reduce carbon emissions and fight climate change.

This research was published by a team from the Helmholtz-Zentrum Berlin (HZB), Physikalisch-Technische Bundesanstalt (PTB), and the universities of Tartu and Tallinn, Estonia. The study’s first author is Rutha Jäger from the University of Tartu, with contributions from Eneli Härk at HZB and other co-authors.