Summary:

• Discarded seashells can be used to make concrete more environmentally friendly.

• Replacing some cement with ground seashell powder can reduce concrete’s carbon emissions by up to 36 percent.

• Using shell waste in construction could help reduce landfill and support more sustainable building practices.

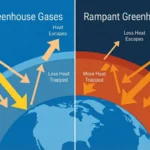

Concrete is one of the most widely used building materials in the world, but it comes with a big environmental cost. The main ingredient in concrete, cement, is responsible for about 7 percent of global carbon emissions. Finding ways to make concrete with a lower carbon footprint is a major challenge for the construction industry.

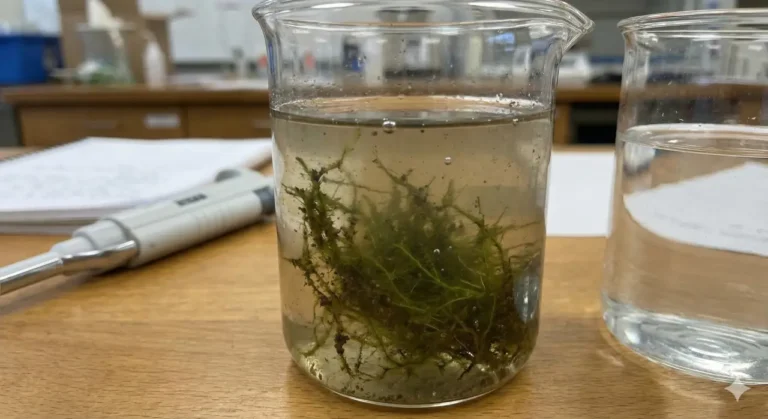

A new study from researchers at the University of East London has found an unexpected helper in this challenge: seashells. Every year, millions of tonnes of shells from seafood processing end up as waste, often sent to landfills or left unused. The research team discovered that these discarded shells, especially scallop shells, can be ground into a fine powder and used in concrete.

By replacing part of the cement in concrete with this shell powder, the researchers were able to cut the carbon emissions linked to concrete production by up to 36 percent. Importantly, the concrete still kept most of its strength and other key qualities, making it a practical option for real-world construction.

The process works because seashells are rich in calcium, a key ingredient in cement. When ground into powder, the shells can fill small gaps in the concrete and help form new binding compounds that hold the material together. This not only reduces the need for cement, but can also improve some aspects of the concrete’s structure.

Using shell waste in this way could benefit both the environment and the construction industry. It helps reduce landfill waste and offers a new use for a material that would otherwise be thrown away. It also provides a simple method for construction companies to lower their carbon emissions, which is increasingly important as governments and clients demand more sustainable building practices.

If further testing shows that shell-based concrete works well on a larger scale, this approach could support a more circular economy, where waste from one industry becomes a resource for another. This would be a step forward for both waste reduction and climate action in the built environment.

The research was published in Construction Materials, an open-access journal from MDPI. The study was led by Dr Ali Abass, Associate Professor of Structural Engineering at the University of East London, with contributions from other co-authors.