Image for Illustration Only.

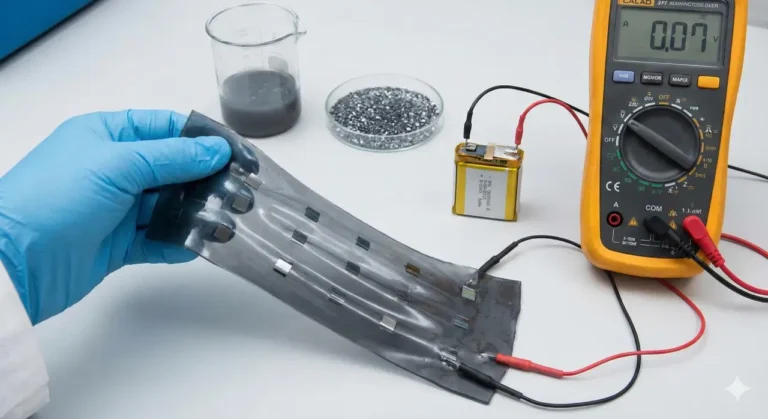

Hydrogen has long been hailed as the “holy grail” of clean energy—a fuel capable of powering heavy industry and transportation without emitting a single ounce of carbon. However, this dream has faced a stubborn economic reality: the scarcity of iridium. This rare metal, currently priced at around $160 per gram, is essential for the electrolyzers that split water into hydrogen fuel.

The reliance on such a scarce resource has created a bottleneck; without reducing consumption, projected demand for electrolyzers could swallow up 75% of the world’s annual iridium supply. But a new innovation from Rice University suggests that the solution isn’t to find more iridium—it is to use drastically less.

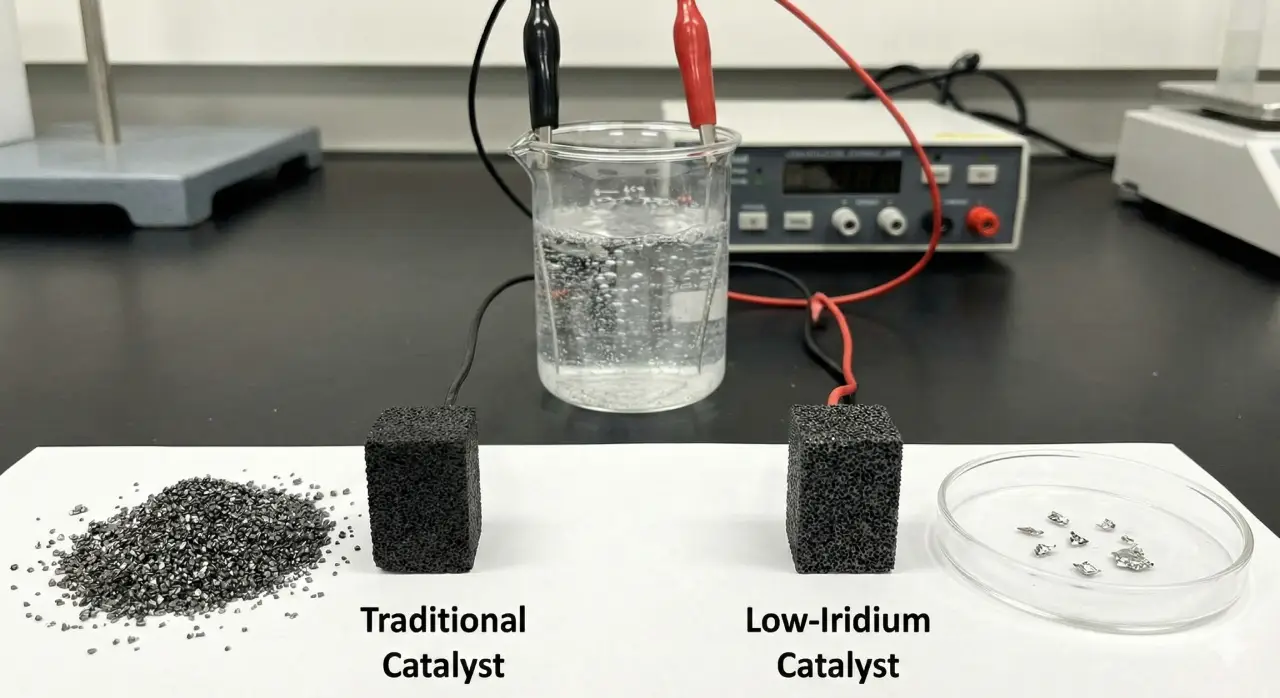

Stabilizing from Within: In a study published in Nature Nanotechnology, engineers revealed a new catalyst that slashes iridium use by 80% while maintaining industrial-level performance. The secret lies in a clever architectural redesign of the material itself.

Typically, iridium is used to shield catalysts from the harsh, acidic conditions inside an electrolyzer. The Rice team, however, used simulations to discover that iridium atoms could be strategically embedded inside a lattice of ruthenium oxide.

Thomas Senftle, a co-author of the study, explains that these subsurface atoms act as a reinforcement, protecting the material from dissolving under extreme conditions. The resulting catalyst, known as Ru6IrOₓ, uses just one-sixth the amount of iridium found in conventional systems but remains stable for over 1,500 hours of continuous operation.

A Path to Affordable Clean Energy: The implications of this “less is more” approach are profound. By replacing conventional iridium oxide with this new hybrid material, manufacturers could cut the cost of the anode catalyst by more than 80%.

This innovation does more than just save money; it removes a critical barrier to entry for the hydrogen economy. As nations invest billions in decarbonization, technologies that decouple growth from resource scarcity are essential. By making electrolyzers more durable and less dependent on rare earth metals, we are moving one step closer to making green hydrogen a truly global, renewable fuel.