Summary:

• Scientists have developed a new fiber made from proteins using yeast, which is strong, biodegradable, and avoids harmful chemicals.

• This new fiber requires far less land and water than cotton, freeing up resources that could be used to grow food.

• The technology could help reduce textile waste and support global efforts to fight hunger and promote sustainability.

Clothing is a part of everyday life, but the way we make fabrics can have a big impact on the planet. Traditional fibers like cotton and polyester come with major environmental challenges. Cotton farming uses huge amounts of water and land, while polyester, a type of plastic, can linger in the environment for decades after being thrown away. But what if there was a better way to make the clothes we wear?

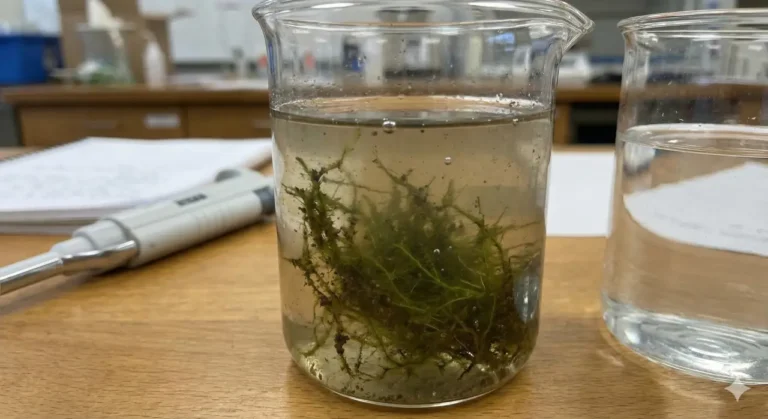

A team of researchers led by Melik Demirel has spent over ten years developing a new type of fiber made from proteins, inspired by how nature builds strong materials. They use yeast, a simple organism, to grow these proteins. The process collects the proteins in a way similar to how certain natural protein structures, called amyloids, form in nature. The proteins are then dissolved in a special solution and pushed through a device called a spinneret, which turns them into long, continuous fibers. After washing and drying, these fibers can be spun into yarn and woven into fabric.

One of the biggest benefits of this new fiber is that it is biodegradable. That means, unlike polyester, it will naturally break down after being thrown away, reducing long-term pollution. The process also uses a solvent—the same kind used to make a plant-based fiber called Lyocell—which can be almost entirely recovered and reused, making the system even more sustainable.

Using proteins to make fibers is not a completely new idea. In the past, materials like Lanital (made from milk protein) and fibers from peanuts or corn were tried, but they were not strong enough and were eventually replaced by cheaper, tougher polyester. The new approach overcomes these problems, creating a strong, high-quality fiber that could compete in today’s market.

The environmental advantages go beyond just reducing waste. Cotton farming takes up about 88 million acres of land worldwide and uses enormous amounts of water. For example, making just one T-shirt and a pair of jeans from cotton can require over 2,600 gallons of water. Much of this farmland is in regions where people struggle with hunger. If less land was needed for fiber crops like cotton, more could be used to grow food, helping address global food shortages.

In 2024, around 733 million people worldwide faced food insecurity. The United Nations has set a goal to end hunger by 2030. By shifting to protein-based fibers made through biomanufacturing, we could reduce the competition between growing crops for clothing and for food. This could help free up resources and move us closer to a world where everyone has enough to eat.

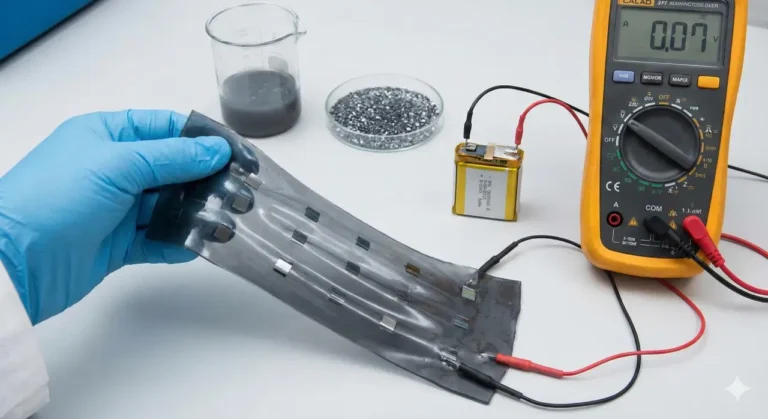

The research team is now working to scale up their process for commercial use. Their pilot projects have shown that the fiber can be produced reliably and could become a real alternative to traditional materials. This new fiber is being developed by a company called Tandem Repeat Technologies, and there are plans to bring it to the mass market soon. If adopted widely, this innovation could help reduce textile waste, lower the environmental impact of clothing, and support efforts to feed a growing global population.

This research was published with contributions from Melik Demirel (lead researcher), Benjamin Allen (chief technology officer), and Balijit Ghotra at Tandem Repeat Technologies, Inc., as well as Birgit Kosan, Philipp Köhler, Marcus Krieg, Christoph Kindler, and Michael Sturm from the Thüringisches Institut für Textil- und Kunststoff-Forschung (TITK) e. V. in Germany. The technology is licensed through the Penn State Office of Technology Transfer. The work was supported by BioMADE and the Defense Industrial Base Consortium through a grant from the U.S. Department of Defense.