Summary :

• Scientists have developed a new membrane that separates hydrogen from carbon dioxide with record efficiency.

• This membrane could help make industrial gas separation much more energy-efficient and reduce carbon emissions.

• The discovery challenges old ideas about how to design membranes for gas separation.

Industrial processes often need to separate gases like hydrogen and carbon dioxide (CO2), but doing so usually takes a lot of energy. In fact, separating chemicals in industry uses up to 15% of the world’s total energy. Finding better ways to do this could make a big difference for the environment and help industries run cleaner and more efficiently.

Traditionally, scientists have designed special filters, called membranes, to attract the gas they want to collect. The idea is that if the membrane “likes” a certain gas, it will let that gas through faster and more easily. But a new study from researchers at the University at Buffalo has found that this approach doesn’t always work as expected.

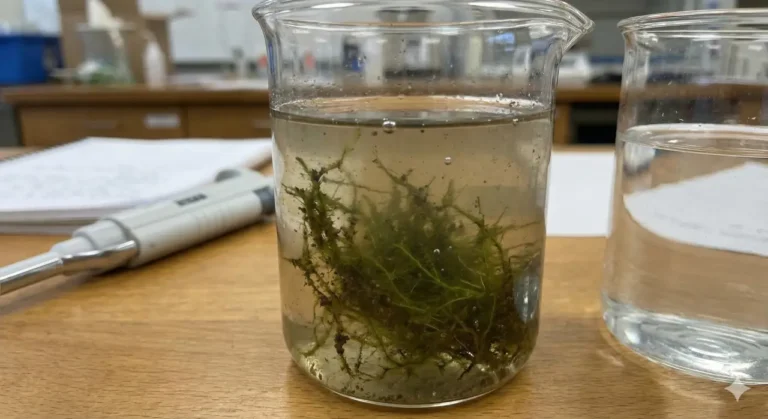

The team studied a membrane made from a material called crosslinked polyamines. These are polymers, or long chains of molecules, that are known to attract CO2. Surprisingly, the researchers found that this attraction was actually too strong. Instead of letting CO2 pass through quickly, the membrane held onto it tightly and slowed it down.

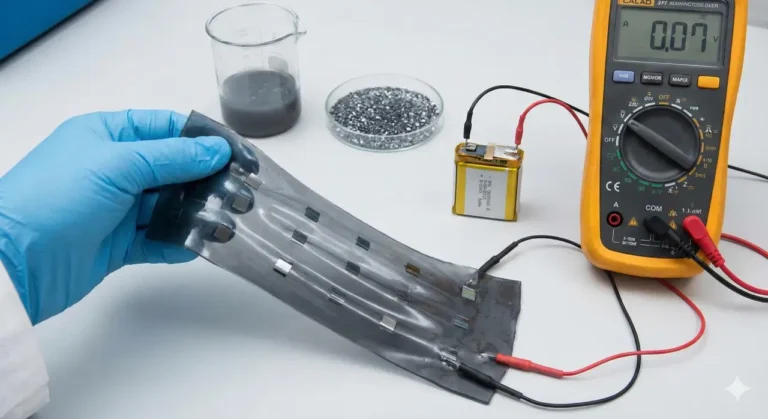

This unexpected result led the scientists to try something new. Since the membrane was so good at blocking CO2, they wondered if it could be used to separate hydrogen from CO2. This is important because hydrogen is a key clean fuel, and it’s often mixed with CO2 during production.

When they tested the membrane, they found that it let hydrogen pass through 1,800 times more easily than CO2—a record-breaking level of selectivity. Previous membranes could only achieve selectivity rates of about 100, so this is a major improvement.

The new membrane has other advantages, too. It can be made into thin films suitable for industrial use, it can repair itself if damaged, and it stays stable even in tough conditions. Because it doesn’t need extra chemicals and uses less energy, it could help make industrial processes much more sustainable.

This discovery also changes how scientists think about designing membranes. It shows that sometimes, making a membrane that strongly attracts one gas can actually help separate it from another, by slowing it down instead of speeding it up.

If this technology is adopted on a large scale, it could play a big role in reducing the energy and emissions from industries that rely on gas separation, helping move us closer to a cleaner future.

This research was published in Science Advances by a team including Haiqing Lin (corresponding author), Leiqing Hu (first author), Kaihang Shi, Peihong Zhang, Asha Jyothi Gottipalli, Gengyi Zhang, Thien Tran, Narjes Esmaeili, Yifu Ding, and Kieran Fung.