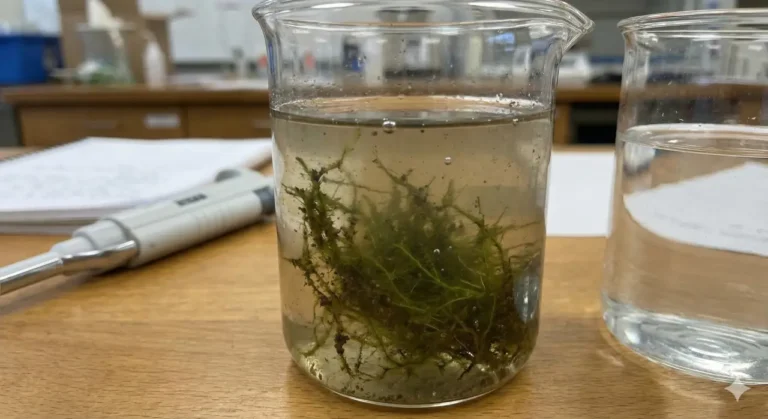

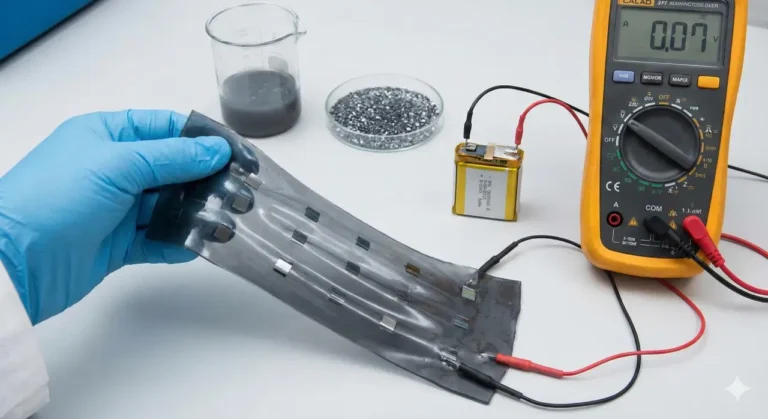

Image for Illustrative Purposes Only.

Summary :

• Scientists are finding ways to use mining waste to make better concrete.

• This new method could help reduce pollution and save natural resources.

• The research supports more sustainable building practices for the future.

Concrete is everywhere in our modern world. From sidewalks to skyscrapers, it’s the backbone of construction. But making concrete uses up a lot of natural resources and creates a large amount of pollution. In fact, concrete production is responsible for about 8 percent of all greenhouse gas emissions worldwide and uses up nearly a third of non-renewable resources each year.

A team of researchers from Flinders University is working to change that. They are exploring how to turn a waste product from lithium mining, called delithiated β-spodumene (DβS), into a valuable ingredient for concrete.

DβS is usually thrown away after lithium is extracted, but it has special chemical properties that make it useful for construction. DβS is described as “pozzolanic,” which means it reacts with other materials in concrete to make the final product stronger and more durable. The researchers found that when DβS is used in geopolymer binders—a type of environmentally friendly cement—it can improve how well the concrete performs over time.

Geopolymer binders are an alternative to traditional cement. They are made from industrial by-products instead of raw materials like limestone. By using DβS in these binders, the researchers not only make use of a waste material but also reduce the need for other ingredients that are often less sustainable, such as fly ash from coal plants.

The team carefully studied how different mixtures of DβS and other chemicals affect the strength and durability of the concrete. They found the best combinations that make the concrete tough and long-lasting. This means buildings and roads made with this new material could last longer and need fewer repairs.

Using mining waste in concrete has several big benefits. It keeps DβS out of landfills, which helps prevent soil and water pollution. It also supports a “circular economy,” where waste from one industry becomes a useful resource for another. This approach can help reduce the environmental impact of both mining and construction.

The research team, led by Dr Aliakbar Gholampour, has published several studies on these new materials. Their work also explores how to make concrete even better by using recycled materials, advanced computer models, and 3D printing technology.

All these efforts point toward a future where buildings are not just strong and safe, but also much kinder to the planet. By finding new uses for industrial waste, scientists are helping to build a more sustainable world—one concrete block at a time.

The studies discussed were published in the journals Materials and Structures, Journal of Materials in Civil Engineering, International Journal of Construction Management, Construction and Building Materials, and Results in Engineering. The research was led by Dr Aliakbar Gholampour (Flinders University), with co-authors Mohammad Kiamahalleh, Youhong Tang, and Tuan Ngo (The University of Melbourne), along with international collaborators.