Summary:

• A new technology uses water and pressure to capture carbon dioxide from industrial emissions

• This method is less expensive and cleaner than traditional chemical-based systems.

• It could help reduce greenhouse gases from power plants and factories, making energy production more sustainable.

Capturing carbon dioxide (CO₂) before it escapes into the atmosphere is a key challenge in fighting climate change. Factories and power plants that burn fossil fuels like coal, oil, or natural gas release large amounts of CO₂, a greenhouse gas that contributes to global warming. Traditionally, capturing this gas has required expensive chemicals and complicated systems. But a new approach, called Pressure Induced Carbon Capture (PICC), offers a simpler and more affordable solution.

How does PICC work: PICC uses a process similar to what happens when you open a bottle of soda or sparkling water. In a sealed bottle, CO₂ is dissolved in the liquid under high pressure. When you open it, the pressure drops and bubbles of CO₂ escape. PICC uses this same principle, but on a much larger scale.

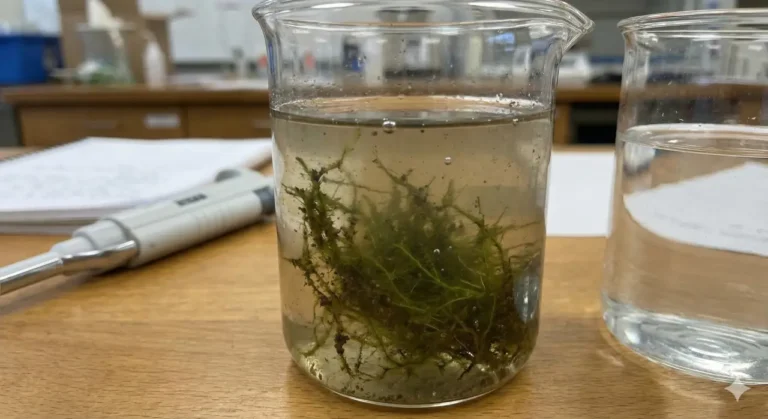

First, the exhaust gas from burning fuel—known as flue gas—is cooled and compressed. This high-pressure gas is then sent into a tall column where cold water flows down while the gas moves up. The design of the column helps the gas and water mix thoroughly. As they interact, CO₂ dissolves into the water, leaving the remaining gases much cleaner as they exit the top of the column.

The water, now carrying the dissolved CO₂, is moved into a series of tanks, each at a lower pressure than the last. As the pressure drops, the CO₂ comes out of the water as bubbles, just like when opening a soda. This CO₂ can then be collected, compressed, and stored underground, keeping it out of the atmosphere.

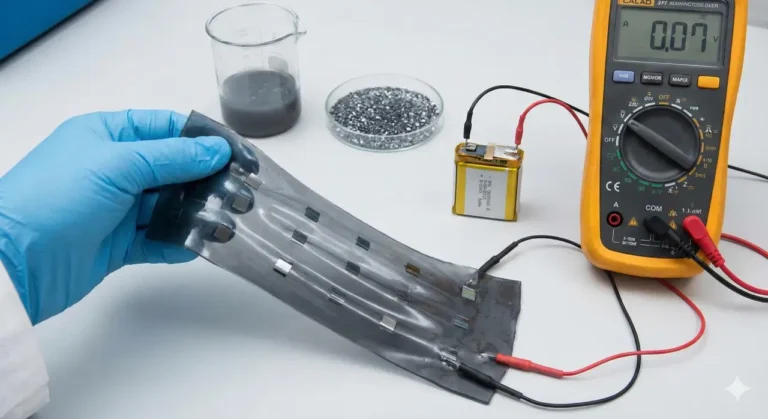

Why is this method important: Most current carbon capture systems use chemicals called amines to trap CO₂. These chemicals are costly, can break down over time, and typically only capture about 90% of the CO₂. This means some greenhouse gases still escape. In contrast, PICC uses only water and pressure—no harsh chemicals—making it cleaner and more environmentally friendly.

Economic studies suggest that PICC can capture and compress 99% of CO₂ emissions at a cost of about $26 per metric ton, which is much cheaper than the $50 to $100 per ton for older methods. If a small amount of lime (a basic mineral) is added to the water, the system can even capture 100% of the CO₂, including that from the air used in combustion, for less than $28 per ton.

What could this mean for the future: This technology could help power plants, cement factories, steel mills, and other industries reduce their carbon footprint without major changes to how they operate. It also opens the door to using fossil fuels more responsibly, since their emissions can be managed more effectively. Additionally, when paired with burning plant-based materials (biomass), PICC could even help remove CO₂ from the atmosphere, offering a path to negative emissions.

By making carbon capture simpler and less expensive, PICC could play a big role in making energy production and industry more sustainable.

Source Attribution:This article is based on research by Dr. Mark Holtzapple (Texas A&M University) and Jonathan Feinstein (ExcelThermic Enterprises), as reported in their patent filings and public statements.